6/8/2023

Press Release

Reducing CO2 Emissions in the Spherical Particle Manufacturing Process to Zero

Reducing CO2 Emissions in the Spherical Particle Manufacturing Process to Zero

Development of Powder Melting and Spheroidizing Technology Using Hydrogen-Pure Oxygen Combustion

Taiyo Nippon Sanso Corporation (“TNSC”, President Kenji Nagata), a Japanese industrial gas company in Nippon Sanso Holdings Group, has developed an inorganic powder melting and spheroidizing technology that can contribute to the achievement of carbon neutrality in the semiconductor materials manufacturing process. The technology combines the CERAMELT® powder melting and spheroidizing system, which uses pure oxygen combustion, with hydrogen combustion technology.

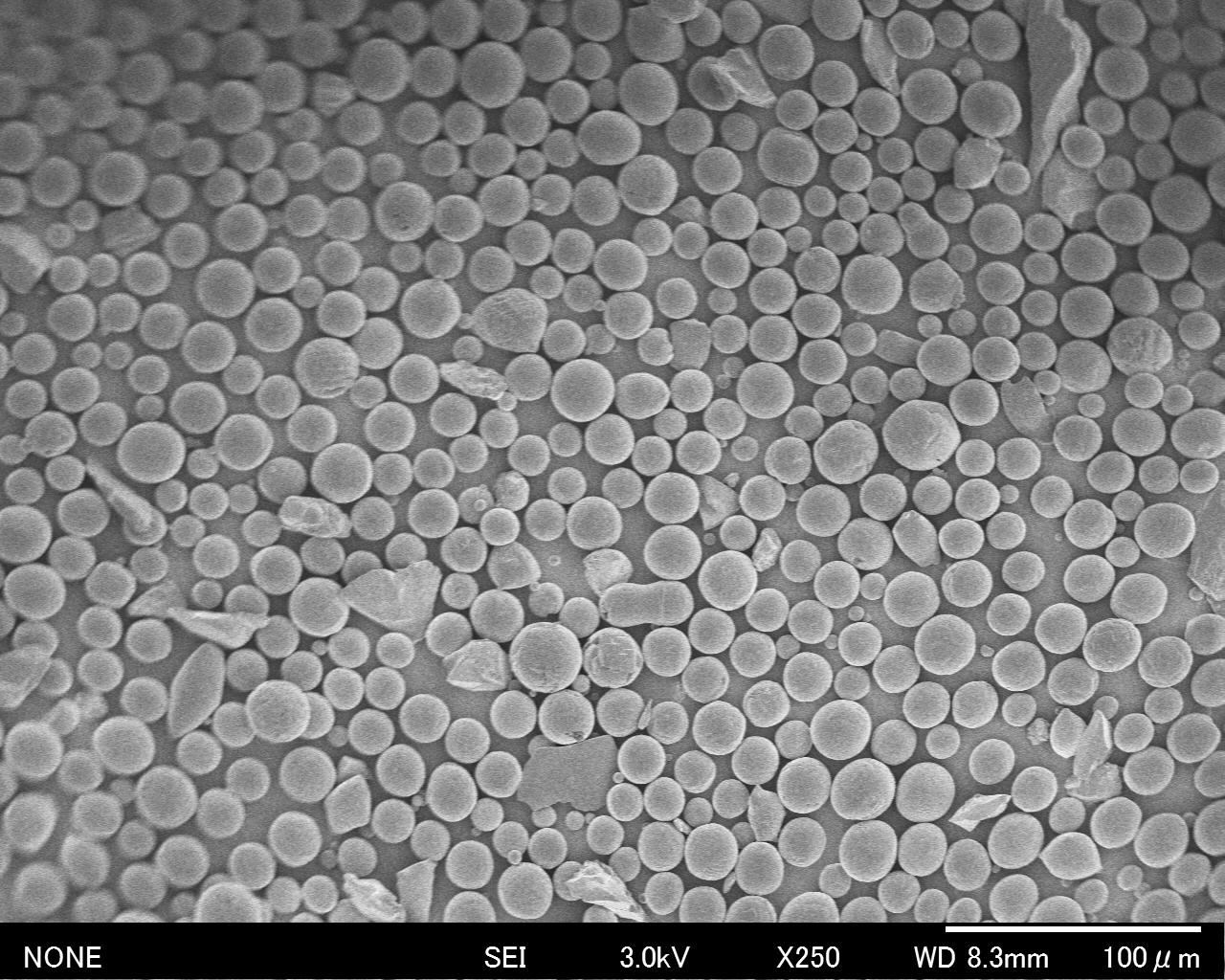

Spherical particles are used as resin filler for semiconductor sealant, etc., contributing significantly to performance increase and miniaturization of semiconductors. CERAMELT® is used in the process of manufacturing spherical particles such as spherical silica, and is characterized by melting and spheroidizing powder by passing the raw material particles through a high-temperature flame using oxygen combustion.

With the recent expansion of semiconductor use, requirements for reducing the environmental impact of the manufacturing process have become more demanding. TNSC has developed a powder melting and spheroidizing technology using hydrogen-pure oxygen combustion to solve this challenge.

CERAMELT® conventionally used fossil fuels such as propane as fuel, and thus contained CO2 in the exhaust gas. This technology uses hydrogen as the fuel, thus reducing CO2 emissions in the exhaust gas to zero. This greatly contributes to the reduction of environmental impact while maintaining the same performance as conventional fossil fuels for melting and spheroidizing the raw material particles. In addition, since no carbon source is supplied to CERAMELT®, carbon impurities in products is reduced, contributing to the manufacturing of high-quality spherical particles. We will work together with our customers to practically implement this technology in the future.

About Taiyo Nippon Sanso

Taiyo Nippon Sanso holds the top share of the Japanese industrial gases market at around 40% and plays a central role in the Japan segment of Nippon Sanso Holdings Group. It has the main R&D and engineering functions for the Nippon Sanso Holdings Group, and a structure that enables it to meet customers’ demands. It supports manufacturing with a nationwide network and stable operations at highly efficient production plants.